S3-Series

Product Description

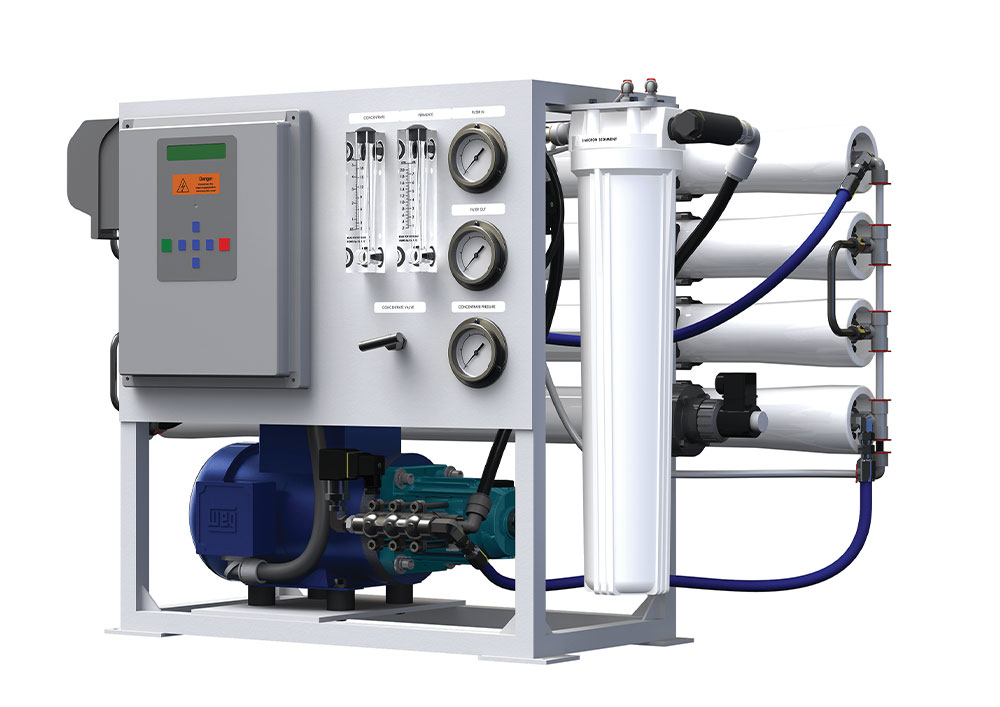

AXEON S3 – Series Reverse Osmosis Systems are engineered and manufactured for seawater applications specifically tailored for capacities ranging from 600 to 2,200 gallons per day. The S3 – Series Reverse Osmosis Systems feature a unique and innovative compact design that allows for easy installation in any size area.

The S3 – Series is also equipped with premium components, which include a 316L SS plunger–type pump for high performance, a high-grade corrosion resistant aluminum frame, a programmable computer controller with many built–in features and fiberglass membrane housings for durability.

Features

Questions?

Do you need further assistance or would link to request a quote? Reach out to a helpful AXEON Team Member by contacting us

Hours Of Operation

Monday thru Friday 7:30 am PST - 4:30 pm PST