Technical Articles

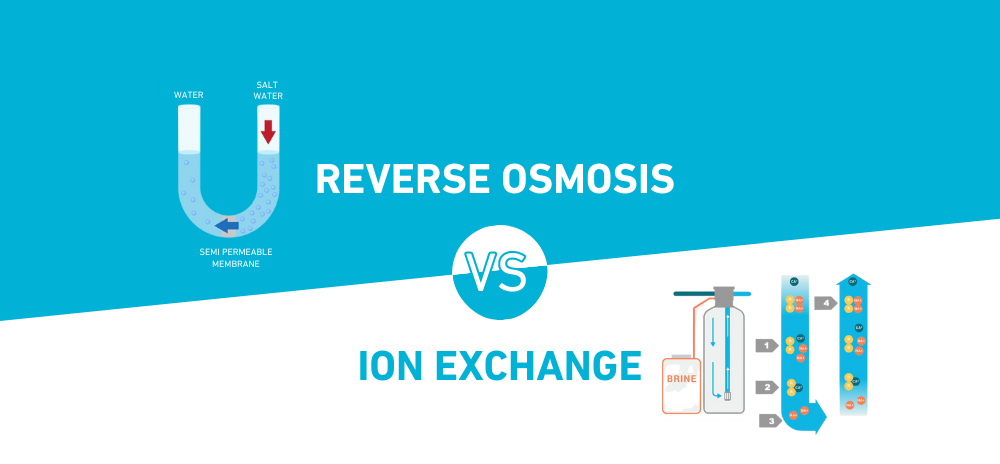

Reverse Osmosis vs. Ion Exchange

What is Reverse Osmosis?

Reverse osmosis is a water treatment method that uses pressure to force water through a semi-permeable membrane, removing impurities such as salts, minerals, and contaminants. This process effectively purifies the water, making it suitable for drinking, cooking, and other applications.

What is Ion Exchange?

Ion exchange is another water treatment method that involves the exchange of ions between a solid resin and the water. It removes unwanted ions from the water by replacing them with desirable ions. This process helps in softening hard water, removing heavy metals, and reducing the concentration of harmful substances.

| Method | Explanation |

| Reverse Osmosis | Uses a semi-permeable membrane to remove ions, molecules, and larger particles. Effectively eliminates contaminants such as lead, fluoride, and bacteria. |

| Ion Exchange | Involves the exchange of ions between two electrolytes or between an electrolyte solution and a complex. Particularly effective in softening water by removing minerals such as calcium and magnesium. |

Importance of water treatment methods

Both reverse osmosis and ion exchange are important water treatment methods that play a crucial role in ensuring clean and safe drinking water. These methods help remove impurities and contaminants, improving the taste, odor, and overall quality of the water. By choosing the appropriate method based on your specific needs and water quality, you can ensure the health and well-being of yourself and your family.

How Reverse Osmosis Works

Reverse osmosis is a water purification process that removes contaminants by using pressure to force water molecules through a semipermeable membrane. This membrane allows pure water molecules to pass through while blocking larger molecules and impurities. The result is clean, purified water.

Process and principles of Reverse Osmosis

During the reverse osmosis process, water is pushed through the membrane, leaving behind total dissolved solids, bacteria, and other contaminants. The pressure applied helps overcome the natural osmotic pressure, allowing the water to flow from a higher concentration of solutes to a lower concentration.

Pros and cons of Reverse Osmosis

Pros:

- Removes a wide range of contaminants, including heavy metals, chemicals, and bacteria.

- Produces high-quality drinking water.

- Requires minimal maintenance.

- Can be installed under the sink or as a whole-house system.

Cons:

- Wastes water during the purification process.

- Removes beneficial minerals along with contaminants.

- Slower filtration rate compared to other methods.

- Initial installation costs can be higher than other filtration systems.

In summary, reverse osmosis is an effective method for purifying water and removing contaminants. However, it is important to consider the pros and cons before deciding if it is the right choice for your specific needs.

How Ion Exchange Works

Process and principles of Ion Exchange

Ion exchange is a water treatment process that involves the exchange of ions between a solid resin and the water. The resin contains charged particles that attract and exchange ions in the water, removing impurities and contaminants. The process works on the principle of electrostatic attraction, where ions with opposite charges are attracted to each other.

During ion exchange, the resin is regenerated by flushing it with a solution that replenishes the charged particles. This allows the resin to continue removing ions from the water effectively.

Pros and cons of Ion Exchange

Ion exchange has several advantages, including its ability to remove a wide range of contaminants, such as heavy metals, nitrates, and hardness-causing minerals. It is also highly effective in improving water taste and odor.

However, there are some drawbacks to consider. Ion exchange systems require regular maintenance and regeneration of the resin. They can also be expensive to install and operate, especially for large-scale applications. Additionally, ion exchange may not be suitable for treating water with high levels of organic matter or certain chemicals.

In summary, ion exchange is a versatile water treatment method that can effectively remove various contaminants. It is important to weigh the pros and cons before deciding if it is the right choice for your specific water treatment needs.

Comparison of Reverse Osmosis and Ion Exchange

Efficiency and effectiveness

When it comes to water treatment, both reverse osmosis (RO) and ion exchange are popular methods. RO is highly effective in removing a wide range of contaminants, including dissolved solids, heavy metals, and bacteria. On the other hand, ion exchange is particularly efficient in removing specific ions like calcium and magnesium that cause hardness in water. The choice between the two methods depends on the specific water quality issues you are facing.

Cost analysis

In terms of cost, reverse osmosis systems tend to be more expensive upfront due to the complex filtration process. However, they require less maintenance and have lower operating costs in the long run. Ion exchange systems may have lower initial costs but can be more expensive to maintain over time due to the need for regular resin replacement.

Maintenance requirements

RO systems generally require less maintenance compared to ion exchange systems. RO membranes need periodic cleaning and replacement, while ion exchange resins need regular regeneration or replacement. The maintenance frequency and costs depend on factors such as water quality, usage, and system design.

In conclusion, both reverse osmosis and ion exchange have their advantages and are effective in different scenarios. It's essential to assess your specific water treatment needs, budget, and maintenance capabilities before choosing the most suitable method for your business or household.

Applications of Reverse Osmosis

Reverse osmosis (RO) is a water purification process that has various applications in both residential and industrial settings. It is commonly used for drinking water purification as well. Here are some key applications of reverse osmosis:

Residential use

The Reverse Osmosis system is widely used in households to remove impurities from tap water, providing clean and safe drinking water. These systems are efficient in removing contaminants such as chlorine, lead, bacteria, and viruses, ensuring the health and well-being of the residents.

Commercial use

Many markets rely on reverse osmosis for daily-to-daily processes such as misting, car wash, aquarium, foodservice and many more. These are uses that are typically needing a reverse osmosis size between 200 - 15,000 gallons per day of purified water.

Industrial use

Many industries rely on reverse osmosis for their water treatment needs. It is used in sectors such as pharmaceuticals, food and beverage production, power plants, and electronics manufacturing. RO systems help remove impurities and ensure the quality of water used in various industrial processes.

Drinking water purification

Reverse osmosis plays a crucial role in providing clean drinking water on a larger scale. It is used in community water treatment plants to remove harmful substances and produce safe drinking water for the population.

In summary, reverse osmosis is a versatile technology that finds applications in residential settings, industrial processes, and large-scale drinking water purification. Its ability to remove impurities and provide clean water makes it an essential tool in ensuring the health and safety of individuals and communities.

Applications of Ion Exchange

Water softening

Ion exchange is commonly used for water softening purposes. Hard water contains high levels of minerals such as calcium and magnesium, which can cause scale buildup in pipes and appliances. Ion exchange resins are used to remove these minerals and replace them with sodium ions, resulting in softened water. This process helps to extend the lifespan of plumbing systems, improve the efficiency of water heaters, and prevent soap scum buildup on surfaces.

Removal of specific contaminants

Ion exchange is also effective in removing specific contaminants from water. By using ion exchange resins with specific properties, it is possible to selectively remove contaminants such as heavy metals, nitrates, arsenic, and radionuclides. This makes ion exchange a valuable tool in water treatment processes, ensuring that drinking water meets regulatory standards and is safe for consumption.

In summary, ion exchange is a versatile technology that finds applications in various industries. Its ability to soften water and remove specific contaminants makes it an essential tool in water treatment processes.

Factors to Consider in Choosing Between Reverse Osmosis and Ion Exchange

When it comes to water treatment systems, two popular methods are reverse osmosis (RO) and ion exchange. Both have their pros and cons, so it's important to consider a few factors before making a decision.

Water quality and composition

The first factor to consider is the quality and composition of the water you need to treat. Reverse osmosis is highly effective in removing impurities like bacteria, viruses, and dissolved solids. It can produce clean and pure drinking water. On the other hand, ion exchange is more suitable for water softening, removing minerals like calcium and magnesium that cause hardness.

If your main concern is removing impurities from your water supply, reverse osmosis might be the better choice. However, if you're dealing with hard water issues, ion exchange can help eliminate scale buildup and improve the taste of your water.

It's important to test your water and understand its specific needs before deciding on a treatment method. Consulting with a water treatment professional can also provide valuable insights into which method is best for your situation.

THE RIGHT SOLUTION FOR YOU

Contact us today for more information about our products and services.

CONTACT US